OUR PRODUCTS

Pressure Gauge

Scientific Controls manufactures pressure measurement and pressure control systems for a ...

Temperature Gauge

Scientific Controls manufactures Temperature Control Systems that measure, indicate and...

Accessories

Scientific Controls has a wide array of Gauge accessories like Needle Valve, Pulsation Dam...

Transformer Temperature Monitoring and Control System

Application For Generator Transformer, Power Transformer, Distribution Transformer, ESP Re...

Bearing Temperature Monitoring and Control System

Application For temperature measurement of the Bearing in large industrial HT/LT, AC/DC in...

ABOUT US

Scientific Controls has been providing control system solutions for manufacturing and industrial processes for over three decades. Established by Mr Vishal Shah, Scientific Controls began manufacturing its own instruments in the year 1990.

The manufacturing process drew on the experiences of Mr. Vishal Shah while trading in control system instrumentation. During his years in the field, he noticed that manufacturers of control systems weren’t able to adapt to the changing needs of the market.

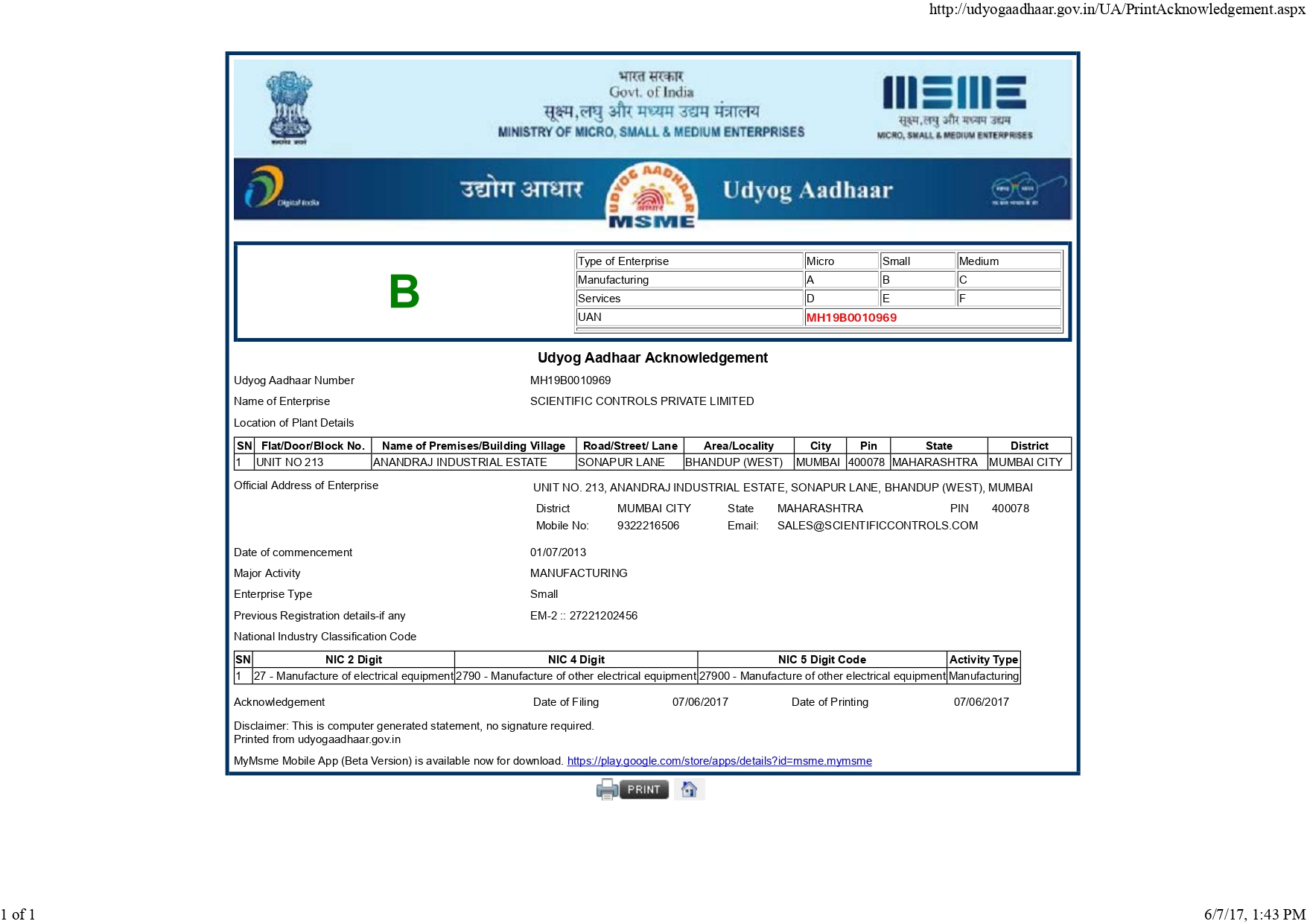

CERTIFICATIONS

CLIENT TESTIMONIALS

Our Clients

Registered Office

Unit - I

- Unit No. 213, Anandraj Industrial Estate, Off. L.B.S. Marg, Behind Asian Paints, Bhandup Sonapur Lane, Bhandup (W), Mumbai - 400078

Unit - II

- Unit No. 212, Anandraj Industrial Estate, Off. L.B.S. Marg, Behind Asian Paints, Bhandup Sonapur Lane, Bhandup (W), Mumbai - 400078

Quick Contact

Opening Hours

- Monday - Saturday

- 09:30 AM - 06:30 PM